The V-RING is a unique all-rubber seal for rotary shafts. Developed in the 1960’s by FORSHEDA AB, it has been used successfully by OEMs and on the replacement market worldwide in a broad range of applications.

The V-Ring is the perfect seal to prevent the ingress of dirt, dust, water or combinations of these media while positively retaining grease. With its unique design and performance the V-Ring can be used with a wide range of bearing types. It can also be used as a secondary seal to protect primary seals that do not perform well in hostile environments.

The V-Ring is normally stretched and mounted directly on the shaft, where it is held in position by the inherent tension of the rubber body. It rotates with the shaft and seals axially against a stationary counterface, perpendicular to the shaft. The counterface can be the side wall of a bearing or a washer, stamping, bearing housing or even the metal case of an oil sea. The sealing lip is flexible and applies only a relatively light contact pressure against the counter-face and yet is still sufficient to maintain the sealing function. The low contact pressure (that varies with the fitted width) allows the seal to run dry in many applications.

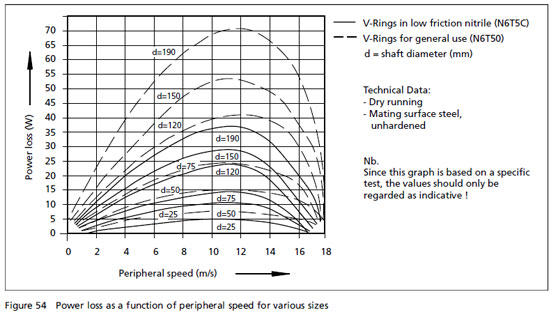

Due to influence of the centrifugal force, the contact pressure of the lip decreases with increased speed. This means that frictional losses and heat are kept to a minimum, resulting in excellent wear characteristics and extended seal life. Once breakaway friction is overcome, the friction reduce steadily until around the 10 – 15 m/s range, when it reduces quite quickly. In the 15 – 20 m/s range the friction reduces to zero. The V-Ring then serves as a clearance seal and deflector. The power loss due to seal friction develops as shown in Fig. 54.

The flexible lip and hinge allow the V-Ring to function even in the presence of a certain amount of run-out, eccentricity and shaft misalignment. Contact our local TSS company for advice on these and other application issues.

V-Rings are made entirely of rubber without fabric or sheet metal reinforcement. They are, therefore, particularly easy to install. V-Rings can be stretched and, depending on size, installed over flanges, pulleys and bearing housings without costly dismantling. For larger sizes they can even be supplied as cut rings and joined by vulcanization of site.

V-Rings are available in seven standard cross-sections to meet various space and application requirements.

The cross-sections of profiles A and S increase with the shaft diameter, whilst the other types have the same cross-section for the whole diameter range.

Profile A is the most common and available for shaft diameters from 2.7 to 2020 mm, inclusive.

Profile S is wide and tapered, which provides a very firm hold on the shaft. The rings are available for shaft diameters from 4.5 to 210 mm.

Profiles L and LX have narrow axial cross sections making them suitable for compact arrangements and are often used in combination with labyrinth seals. Available for shaft diameters from 105 (135 for LX) to 2025 mm.

Profiles RME, RM and AX are heavy duty V-Rings that are designed primarily for large high speed bearing arrangements, I.E. rolling mill and papermaking machine applications. Additionally they can be used as secondary seals for heavy duty applications where the primary seal has to be protected against water and or particulate contamination. The RME, RM and AX types can be axially and radially located on the shaft with the especially designed clamping bands. Available for shaft diameters from 300 mm and up.

Larger V-Ring sizes are available as spliced seals. For more details please contact your local TSS company.

When selecting the correct rubber compound it is necessary totake the following requirements into account;

- -good chemical resistance

- -good resistance to high and low temperatures

- -good resistance to ozone and weathering

It is also necessary to consider the need for the following attributes;

- -high resistance to wear

- -low friction

- -low compression set

- -good elasticity

|