Material Compatibility |

|||||||||||||||||||||||||||||||||||

|

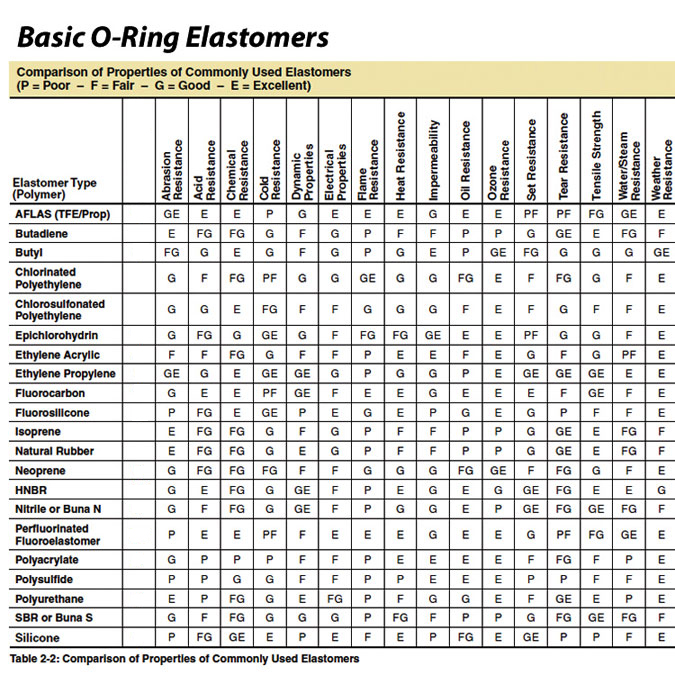

The First step is to consider the materials physical properties because choosing the correct material always involves tradeoffs in performance, as illustrated in the following chart. This process is summarized by the following chart:

The next step is to consider Chemical Compatibility. We will need to consider questions like:

|