Nothing escapes our seals |

||||||||||||||||||||||||

|

O-RINGS AND RELATED PRODUCTS - O RING GASKET, FUEL O-RINGSAll Seals stocks one of the world’s largest inventories of O-Rings, back-up rings, Quattro Seals, O-ring gaskets and much more, all ready for delivery when you need them. Our warehouse stock includes rubber O-Rings in all popular materials, PTFE O-Rings and back-up rings, plus specialty O-Rings for food contact and drinking water applications. We also accomodate your needs with same-day shipping, electronic data interchange (EDI), bar-coding, just-in-time (JIT) programs, custom parts, kitting, parts washing and more. Questions? Just call (800) 553-5054 and speak directly to one of our experts. O-Rings

All Seals also offers a wide array of metric and non-standard O-Rings. As a subset of the metric sizes offered, we stock many Japanese Industrial Standard (JIS B2401) sizes. If a special size or specific chemical resistance is required, All Seals can provide custom O-Rings, specially made to your demanding requirements. Four-lobed Seals™

Four-lobed seals can be used in standard O-Ring, Quad Rings grooves or in deeper four-lobed seals with specific grooves, resulting in less friction and longer seal life. Four-lobed seal grooves can also be narrower than O-Ring grooves, as spiral failure is less of an issue. For four-lobed seal groove recommendations, please go to our Groove Design Chart for Four-Lobed Seals. All Seals stocks many different AS568 sized four-lobed in either 70 durometer nitrile or 75 durometer Viton™. Teflon® Encapsulated O-Rings

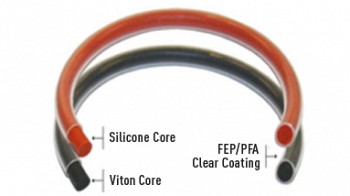

All Seals's Chem-RING Teflon® Encapsulated O-Rings are solvent-resistant and chemically inert (except for attack by alkaline metals, fluorine and some halogenated compounds at high temperatures), yet have an elastomeric memory near that of rubber O-Rings. The more commonly specified FEP encapsulation also has an extremely low coefficient of friction (.1 to .2) and very low permeability to gases, making CHEM-RINGS virtually a universal seal for use in hostile environments. Back-Up Rings

There are three options to prevent extrusion failure, the first of which is to tighten the clearances to reduce the extrusion gap. This can be a costly option; a less expensive solution is to increase the hardness of the O-Ring. Although a higher durometer O-Ring offers superior extrusion resistance, it is often not a feasible solution due to material availability. What’s more, harder durometer materials have limited low pressure sealability. The third and best option is the addition of a back-up ring, made from a hard, extrusion resistant material such as high durometer nitrile, nylon, Hytrel®, or PTFE. Back-up rings are designed to fit between the O-Ring and the extrusion gap, thus minimizing the probability of extrusion failure. While back-up rings are used in conjunction with O-Rings in both static and dynamic sealing applications, the gland they fit in must be specially designed to accomodate both the O-Ring and the back-up. For more information on gland design please visit All Seals's static or dynamic gland design guides.

O-Ring Kits

All All Seals O-Ring and seal kits come in sturdy compartmented boxes made of either translucent polypropylene or opaque/transparent styrene plastic. Each container includes helpful cards or labels indicating size and quantity of seals in each compartment. In order to facilitate resale, all our assortments are shipped in plain boxes with generic labeling for easy re-labeling and re-shipment.

Accessories

O-RING MEASUREMENT CONEA very useful tool for accurately checking O-Ring sizes. All Seals's O-Ring measurement cone is the ideal tool for quick and easy identification of standard AS568 O-Rings. It measures 184 widely used sizes, from 1/4" thru 5-5/8" ID, in five standard cross-sections. The O-Ring measurement cone is made from extremely durable, high density yellow polypropylene and stands a full 17.5 inches tall. This is a must have for any distributor or repair shop that sells O-Rings over the counter. INSTALLATION TOOLS

These tools are a must for anyone who frequently installs rod seals or O-Rings. Patented by All Seals, these tools are a must have for anyone who often installs rod seals or O-Rings. Frequently, these seals need to be placed in small, closed diameter gland openings or deeply set rod grooves. This tool is specifically designed to help with this situation. The rod seal installation tool works by allowing the seal to be held securely, while bending it to reduce the overall outer diameter. Once the bottom untwisted portion of the seal is in the groove, the tool can be released and removed. Installation is completed by snapping the remaining part of the seal into the groove. This tool comes in three different sizes:

O-RING LUBRICANT

A high viscosity, 100% silicone fluid O-Ring lubricant. Seal-Lube is a high viscosity, 100% silicone fluid, primarily used as a lubricant during O-Ring installation. On some applications, where clearances are tight, our silicone lube can be the difference between an easy installation and hours of frustration. Proper lubrication of O-Rings also extends seal life. Two-ounce squeeze bottle facilitates application of lubricant. |

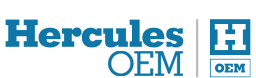

Of the multitude of different O-Ring dimension standards in existence, the most popular in the United States is AS568. Formerly known as ARP 568, and currently maintained by the Society of Automotive Engineers, AS568 lists 369 sizes of O-Rings with corresponding dimensions and tolerances. This standard offers O-Rings in five different cross-sections, with inside diameters ranging from 1/32" to 26". Tube fitting boss seals are included in AS568 as "-900" series O-Ring sizes, and are intended for use in MS33649 (now superseded by SAE-AS5202) straight thread tube fittings.

Of the multitude of different O-Ring dimension standards in existence, the most popular in the United States is AS568. Formerly known as ARP 568, and currently maintained by the Society of Automotive Engineers, AS568 lists 369 sizes of O-Rings with corresponding dimensions and tolerances. This standard offers O-Rings in five different cross-sections, with inside diameters ranging from 1/32" to 26". Tube fitting boss seals are included in AS568 as "-900" series O-Ring sizes, and are intended for use in MS33649 (now superseded by SAE-AS5202) straight thread tube fittings.  Four-lobed seals feature a geometry that provides twice the number of sealing surfaces compared to standard O-Rings. Doubling the number of sealing surfaces allows a four-lobed seal to perform at lower pressures and/or with less squeeze than a standard O-Ring. The four-lobed configuration also creates a more stable seal that reduces the likelihood of spiral twisting in reciprocating applications. This is because rather than relying solely on squeeze to achieve a seal, four-lobed seals employ both squeeze and deflection to create the seal.

Four-lobed seals feature a geometry that provides twice the number of sealing surfaces compared to standard O-Rings. Doubling the number of sealing surfaces allows a four-lobed seal to perform at lower pressures and/or with less squeeze than a standard O-Ring. The four-lobed configuration also creates a more stable seal that reduces the likelihood of spiral twisting in reciprocating applications. This is because rather than relying solely on squeeze to achieve a seal, four-lobed seals employ both squeeze and deflection to create the seal. Elastomeric, rubber O-Rings are susceptible to high friction and limited resistance to aggressive chemicals and gas permeation. Solid PTFE O-Rings are rigid with no effective memory and high compression set. CHEM-RING™ Teflon® Encapsulated O-Rings combine the resilience and sealing force of an elastomer with the chemical resistance of Teflon®. This is accomplished by the use of an elastomeric core of silicone or Viton™ with a relatively thin encapsulation of Teflon® FEP or PFA fluoropolymer. The result is an elastomeric PTFE seal with enhanced sealing capability.

Elastomeric, rubber O-Rings are susceptible to high friction and limited resistance to aggressive chemicals and gas permeation. Solid PTFE O-Rings are rigid with no effective memory and high compression set. CHEM-RING™ Teflon® Encapsulated O-Rings combine the resilience and sealing force of an elastomer with the chemical resistance of Teflon®. This is accomplished by the use of an elastomeric core of silicone or Viton™ with a relatively thin encapsulation of Teflon® FEP or PFA fluoropolymer. The result is an elastomeric PTFE seal with enhanced sealing capability. Extrusion is one of the most common types of O-Ring failure. When the internal systemic pressure of an application becomes too great, the O-Ring will frequently extrude into the clearance gap between mating parts. In many instances, this extrudate will be nibbled away causing a loss of material, with seal failure quickly following.

Extrusion is one of the most common types of O-Ring failure. When the internal systemic pressure of an application becomes too great, the O-Ring will frequently extrude into the clearance gap between mating parts. In many instances, this extrudate will be nibbled away causing a loss of material, with seal failure quickly following.

All Seals offers over twenty-five different O-Ring and seal assortments in numerous materials and sizes. The materials we offer range from standard compounds such as multipurpose Nitrile (Buna-N) rubber, to more exotic materials including Viton™ (generically called fluorocarbon) and PTFE (also called Teflon®).

All Seals offers over twenty-five different O-Ring and seal assortments in numerous materials and sizes. The materials we offer range from standard compounds such as multipurpose Nitrile (Buna-N) rubber, to more exotic materials including Viton™ (generically called fluorocarbon) and PTFE (also called Teflon®). All Seals offers several tools and lubricants that simplify O-Ring identification or installation. From accurate measuring to easy installation tools, they’re must-haves for repair shops or distributors that sell O-Rings over the counter. Each of these accessories comes with instructions.

All Seals offers several tools and lubricants that simplify O-Ring identification or installation. From accurate measuring to easy installation tools, they’re must-haves for repair shops or distributors that sell O-Rings over the counter. Each of these accessories comes with instructions.