O-Rings - Application Details |

|||||||||||||

|

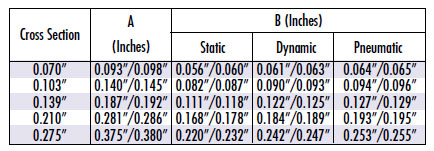

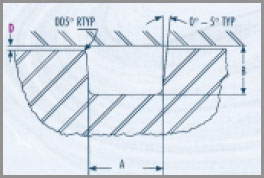

'O' RING GROOVE SIZEAll Seals CHEM-RINGS are designed to be used in all standard 'O' Ring grooves with the same housing dimensions and clearances as for standard elastomeric seals. Our recommendations for BS 1806/AS 568 Imperial Standard 'O' Ring grooves are tabulated below for the standard groove design show below.

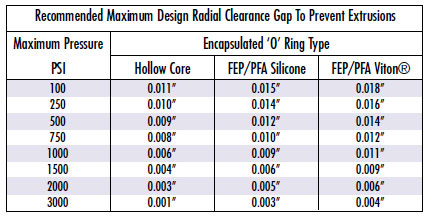

SEAL EXTRUSION RADIAL CLEARANCE GAPS (D on above diagram)

INSTRUCTIONS FOR INSTALLING CHEM-RINGS

The degree of squeeze best recommended is;

COMPRESSION SETAll Seals CHEM-RINGS resist hardening and embrittlement due to the TEFLON® FEP encapsulation. The 'O' Seals retained elasticity and recovery properties at temperatures up to 205°C., is due to the Silicone or Viton™ core material. The results of compression set tests, which compare the retained sealing force of perfluoroelastomers, fluoroelastomers and FEP Encapsulated 'O' Rings can be observed in the following diagram. The results of these tests demonstrate that, by combining the mechanical properties of Viton™ or Silicone elastomers and the chemical resistance of TEFLON® FEP/PFA resins, the CHEM-RING possesses the ability to resist compression set and retain its mechanical properties.

|